Industrial Biomass Boiler

SZL Biomass Chain Grate Boiler

- Capacity: 4~40 t/h, 2.8~28 MW

- Pressure: 1.25~2.5 Mpa

- Steam Temperature: 194/225 ℃

- Thermal Efficiency: >83%

- Fuel: Agricultural and forestry wastes, molded lees, bagasse, biomass pellet, wood etc.

- Food processing, clothing factory, greenhouse heating, catering, building materials, petrochemical and other industries

Introduction of Industrial Chain Grate Biomass Boiler

SZL series industrial biomass boiler adopts double-cylinder vertical structure, the combustion method is chain grate, and the fuel is clean energy biomass (not only does not generate waste gas, waste, and waste smoke during the combustion process, but also has low cost and is easy to operate and relize reuse of biomass waste). This boiler consists of the upper body heating surface and the lower part of the combustion equipment. The fuel is burned in the combustion equipment, and the generated flue gas enters the tail flue through the furnace, the embers chamber, the convection tube bundle, etc., and is then discharged into the atmosphere through a dust collector, an induced draft fan and a chimney.

SZL biomass boiler adopts membrane water-cooled wall structure on both sides of the furnace, which not only improves the tightness of the boiler, but also increases the volume and heating surface of the furnace. It is even better that secondary air is arranged on the front and rear walls (controlled by valves), which not only makes the fuel fully burned, improves the combustion efficiency and thermal efficiency, reduces the fuel cost input, but also reduces the generation of waste and waste residue. What’s even better is that it also has the advantages of high automation level, safe and stable operation, and perfect protection functions, making it an ideal choice for many enterprises.

Industrial Biomass Boiler Features

- The convection arrangement heating surface has high heat exchange efficiency, and the boiler operation efficiency is stable.

- The chain grate, the front and rear smoke box panels are all cut by CNC plasma cutting machine, neat and beautiful.

- The boiler has a large volume and complete internal devices.

- The boiler has functions such as automatic adjustment of water feeding, automatic alarm of high and low water levels, automatic protection of overpressure, and automatic protection of flameout.

- The boiler runs smoothly and has a certain overload capacity.

- The front and rear arches match reasonably, the coverage of the boiler arch is large, and the furnace temperature is high.

- Double-cylinder structure, high combustion efficiency, saving 5-10% of operating costs.

- The cross-section ratio of the falling surface of each heating surface to the rising tube is reasonable, and the combustion conditions are stable.

- The amount of air required for different fuels and different combustion stages in each air chamber can be adjusted artificially, and the lateral wind pressure is consistent, so there is no partial burning.

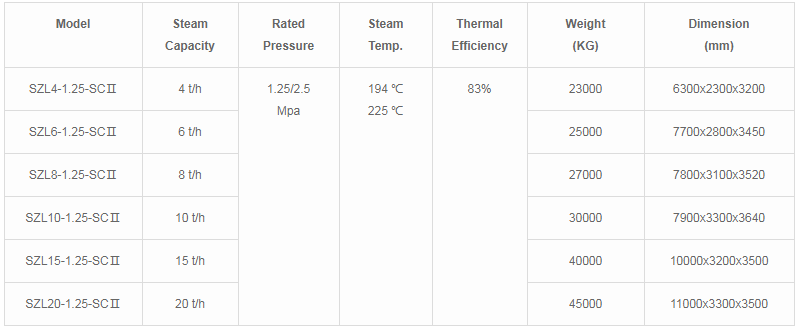

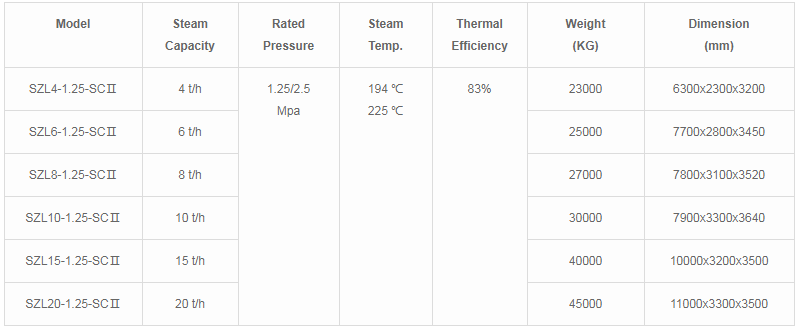

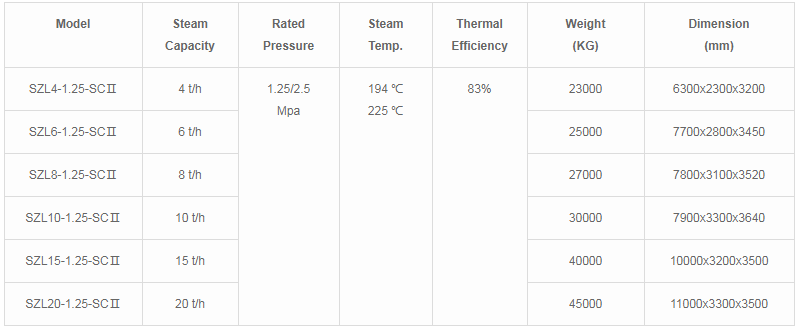

Technical Specification

| Model | Steam Capacity | Rated Pressure | Steam Temp. | Thermal Efficiency | Weight (KG) | Dimension (mm) |

| SZL4-1.25-SCⅡ | 4 t/h | 1.25/2.5 Mpa | 194 ℃ 225 ℃ | 83% | 23000 | 6300x2300x3200 |

| SZL6-1.25-SCⅡ | 6 t/h | 25000 | 7700x2800x3450 | |||

| SZL8-1.25-SCⅡ | 8 t/h | 27000 | 7800x3100x3520 | |||

| SZL10-1.25-SCⅡ | 10 t/h | 30000 | 7900x3300x3640 | |||

| SZL15-1.25-SCⅡ | 15 t/h | 40000 | 10000x3200x3500 | |||

| SZL20-1.25-SCⅡ | 20 t/h | 45000 | 11000x3300x3500 |

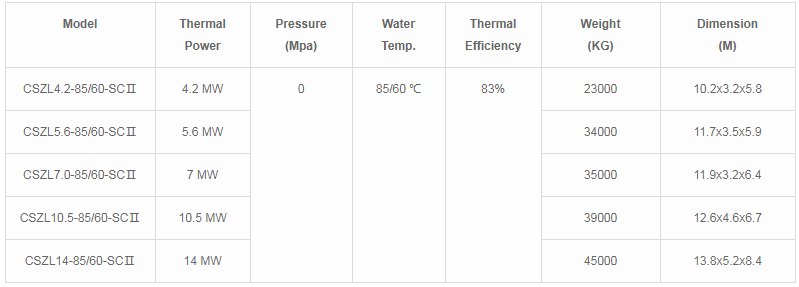

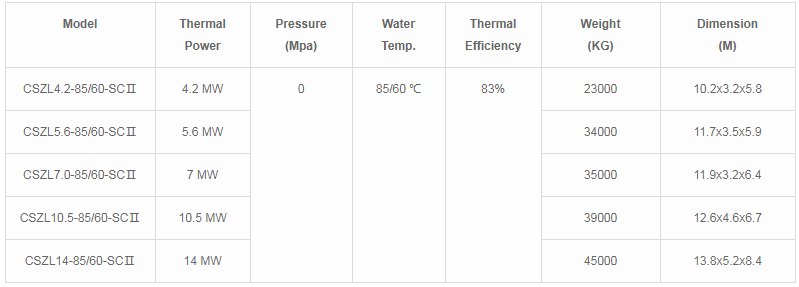

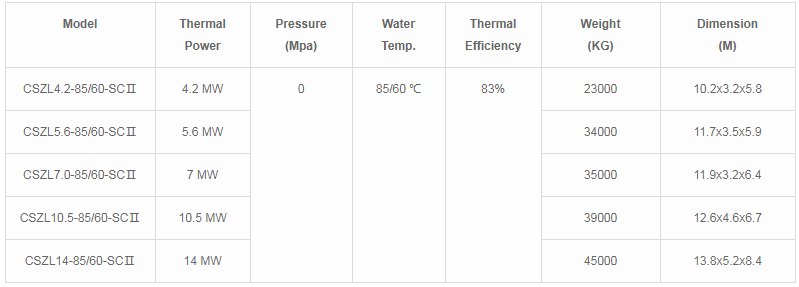

| Model | Thermal Power | Pressure (Mpa) | Water Temp. | Thermal Efficiency | Weight (KG) | Dimension (M) |

| CSZL4.2-85/60-SCⅡ | 4.2 MW | 0 | 85/60 ℃ | 83% | 23000 | 10.2×3.2×5.8 |

| CSZL5.6-85/60-SCⅡ | 5.6 MW | 34000 | 11.7×3.5×5.9 | |||

| CSZL7.0-85/60-SCⅡ | 7 MW | 35000 | 11.9×3.2×6.4 | |||

| CSZL10.5-85/60-SCⅡ | 10.5 MW | 39000 | 12.6×4.6×6.7 | |||

| CSZL14-85/60-SCⅡ | 14 MW | 45000 | 13.8×5.2×8.4 |

| Model | Thermal Power | Pressure | Water Temp. | Thermal Efficiency | Weight (KG) | Dimension (M) |

| SZL4.2-1.0/115/70-SCⅡ | 4.2 MW | 1 Mpa | 115/70 ℃ | 83% | 23000 | 10.2×3.2×5.8 |

| SZL5.6-1.0/115/70-SCⅡ | 5.6 MW | 34000 | 11.7×3.5×5.9 | |||

| SZL7.0-1.0/115/70-SCⅡ | 7 MW | 35000 | 11.9×3.2×6.4 | |||

| SZL10.5-1.0/115/70-SCⅡ | 10.5 MW | 39000 | 12.6×4.6×6.7 | |||

| SZL14-1.0/115/70-SCⅡ | 14 MW | 45000 | 13.8×5.2×8.4 |