Biomass Thermal Oil Boiler

YGL Biomass Thermal Oil Boiler

- Thermal Power: 120KW-1000KW

- Rated Pressure: 0.7/1.0 Mpa

- Oil Temperature: 290/310 ℃

- Thermal Efficiency: >83%

- Fuel: Agricultural and forestry waste, Straw, straw, rice husk, peanut husk, corn cob, camellia husk, cottonseed husk, wood chips, biomass pellets, wood pellet.

Introduction of YGL Biomass Thermal Oil Boiler

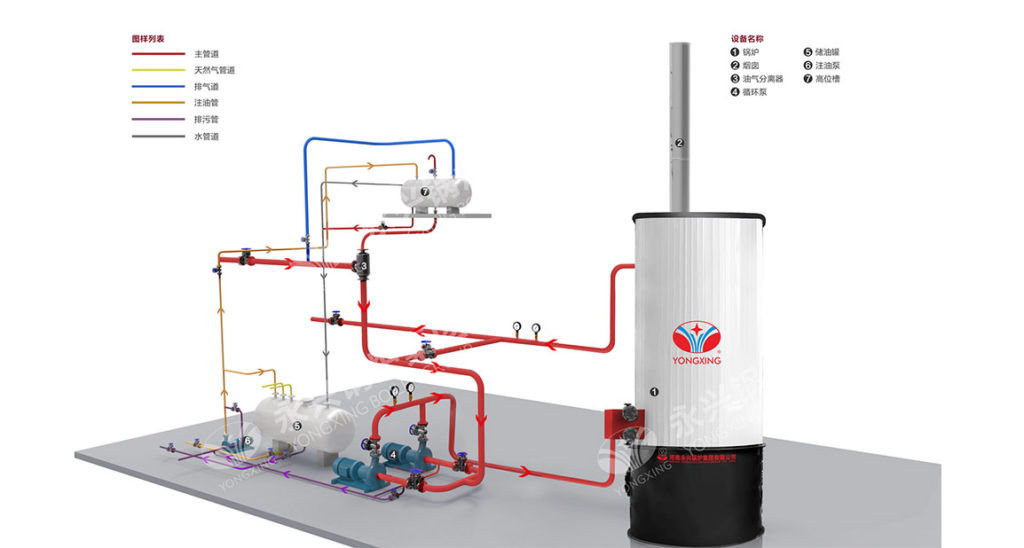

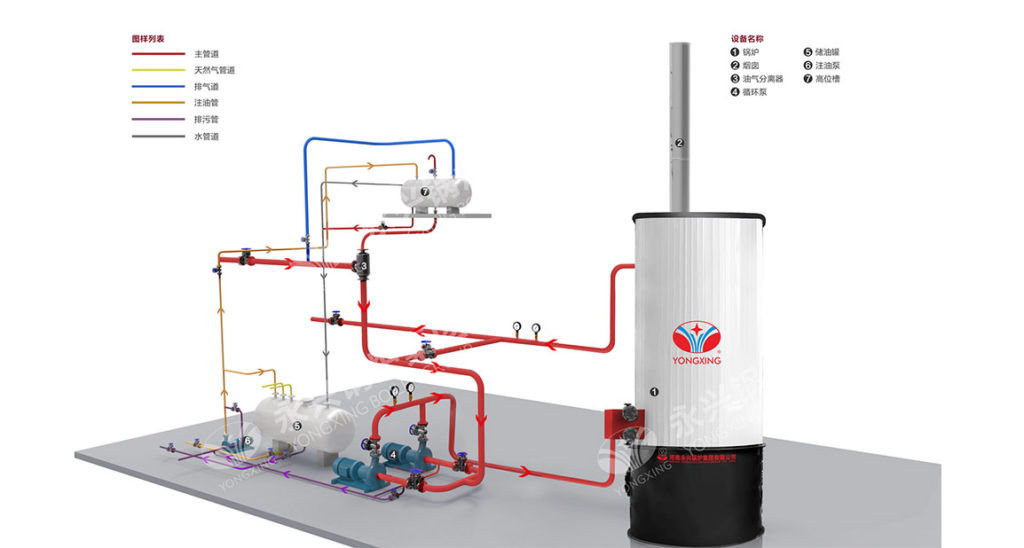

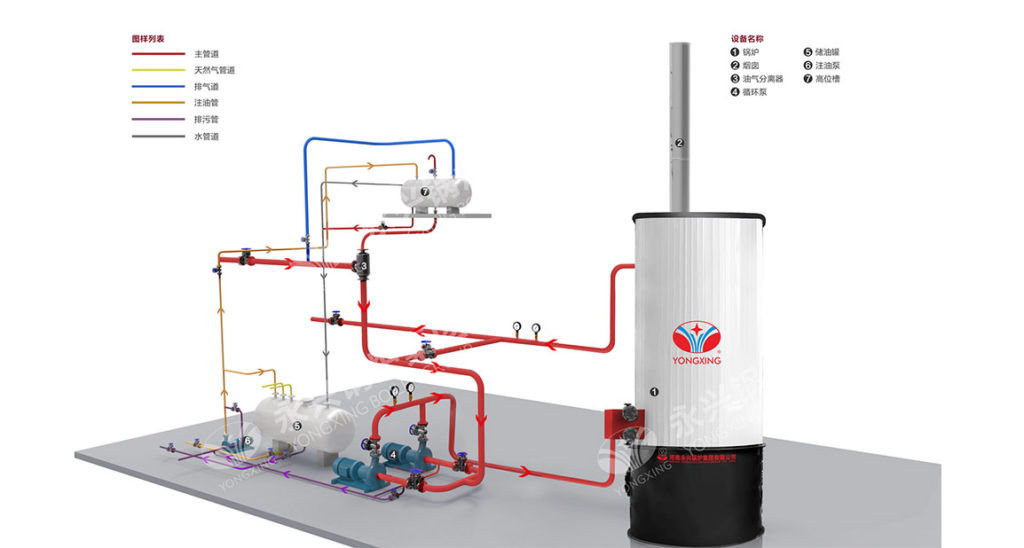

YGL biomass thermal oil boiler, which uses biomass pellets as fuel and heat-conducting oil as a medium, uses a circulating oil pump to force the heat-conducting oil to perform liquid-phase circulation, transfers heat energy to a heating device, and then returns to the heating furnace to reheat. This forced circulation vertical biomass thermal oil boiler is an ideal heating equipment. It adopts a three-return coil design with sufficient heating surface and sufficient expansion to absorb, achieving low-pressure and high-temperature heating. It can also add energy-saving devices, make the boiler more energy-efficient to transport.

The YGL type biomass heat-conducting oil furnace produced by Yongxing Boiler has low-pressure and high-temperature working characteristics.The heating temperature can reach 340℃ in the liquid phase. Therefore, where uniform heating is required and direct flame heating is not allowed, It can be used in various production at 150-380 ℃. Even better, the boiler has the advantages of high heat utilization rate, good heat transfer performance, safe and reliable operation, perfect protection function, convenient operation and maintenance, etc., and has unparalleled advantages of other equipment.

Biomass Thermal Oil Boiler Features

- Using biomass pellets as fuel, turning waste into treasure, saving energy and reducing emissions, meet environment protection policy requirements.

- YGL-type biomass heat-conducting oil boiler provides closed-loop heating, communicates with the atmosphere, and prolongs the service life.

- In the combustion chamber, the fuel is adiabatic, which makes it easier to catch fire and burns more fully, which improves thermal efficiency.

- During the operation of the boiler, it only bears the pump pressure, and the thermal oil has no danger of explosion.

- Liquid phase circulating heating, no heat loss due to condensate discharge, high thermal efficiency of heating system.

- The top of the boiler is arranged with close-packed coils to avoid the burnout of the top of the boiler.

- The boiler is easy to adjust and provides uniform heat, which can meet the precise process temperature.

- In order to cope with the volume change caused by the temperature rise and fall of the working medium, we have added compensation technology measures in the system.

- When installing, as long as the upper body and the lower combustion chamber are closed, it is very simple and convenient, shortening the installation time.

- The heating surface is composed of inner and outer close-packed disk tubes, which reduces the heat load on the surface of the tube and makes the heat transfer oil safer.

Technical Specification

| Model | Thermal Power (x10^4 kcal/h) | Rated Pressure (Mpa) | Max Temp (℃) | Thermal Efficiency (%) | Oil Circulation Volume (m3/h) | Heating Area (m2) | Oil In Boiler (m3) | Weight (kg) | Dimension (mm) |

| YGL-120T | 10 | 0.7/1.0 | 290/310 | 83 | 12.5 | 7.3 | 0.06 | 3000 | 840×1608 |

| YGL-240T | 20 | 20 | 16.3 | 0.19 | 3300 | 1250×2080 | |||

| YGL-350T | 30 | 30 | 22.4 | 0.26 | 3600 | 1350×2050 | |||

| YGL-500T | 40 | 40 | 30.8 | 0.37 | 4000 | 1450×2300 | |||

| YGL-700T | 60 | 60 | 44 | 0.5 | 4500 | 1750×2680 | |||

| YGL-1000T | 80 | 80 | 63.2 | 0.7 | 5100 | 1750×2990 | |||

| YGL-1200T | 100 | 100 | 71 | 0.8 | 5400 | 2250×3030 | |||

| YGL-1400T | 120 | 140 | 87.6 | 1.05 | 6000 | 2250×3140 |