Industrial Biomass Boiler

Wood Steam Boiler with Chain Grate

- Capacity: 0.5~10 t/h, 0.35~7 Mw

- Pressure: 1.25 Mpa

- Steam Temperature: 194 ℃

- Thermal Efficiency: >83%

- Fuel: Rice husks, wood chips, bagasse, solid fuels, biomass pellets, etc.

- Food, rubber, chemical, pharmaceutical, building materials, washing, textile and other industries

Introduction of Chain Grate Wood Fired Steam Boiler

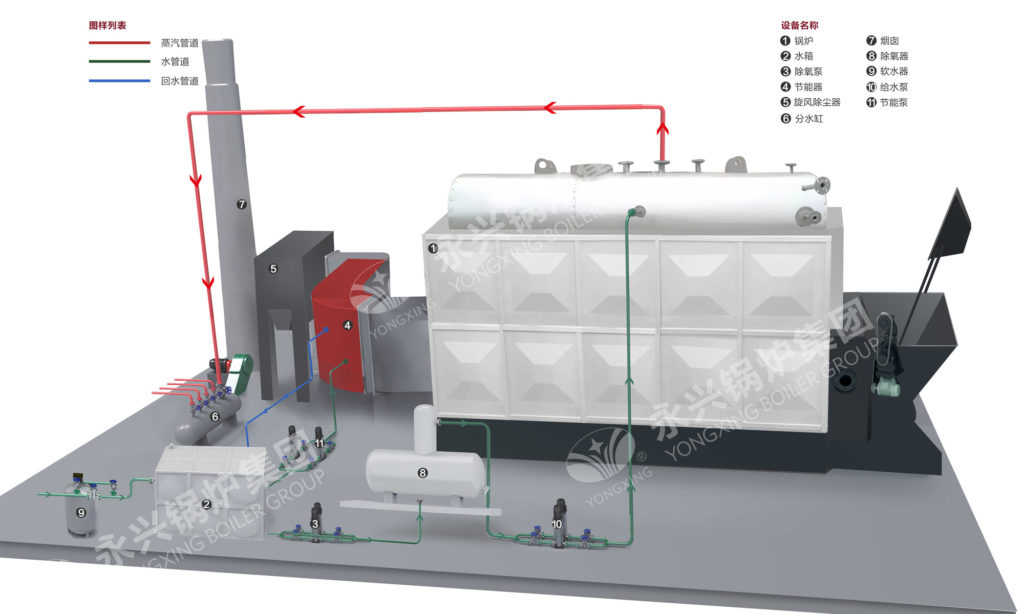

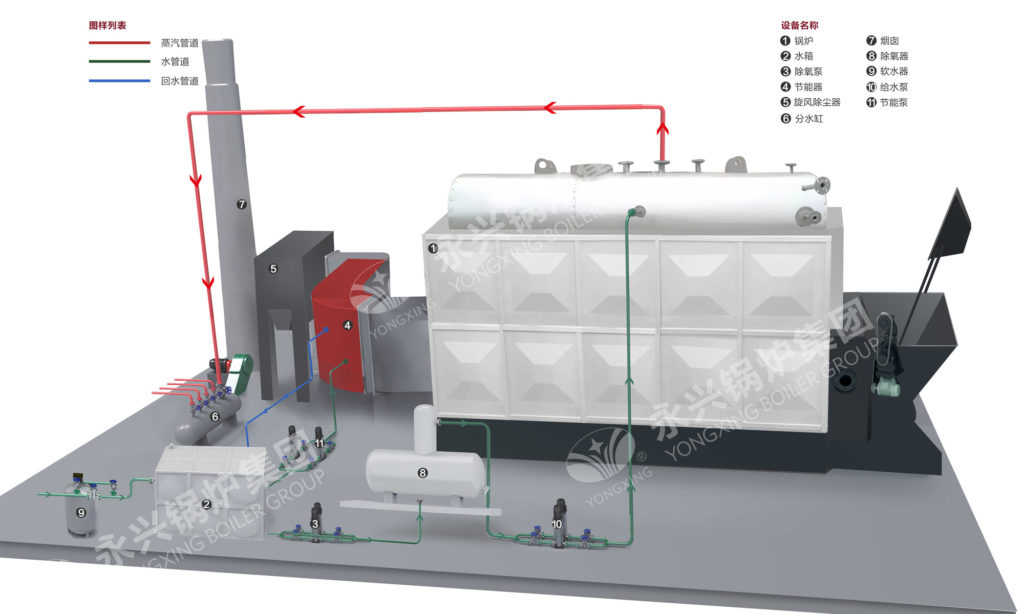

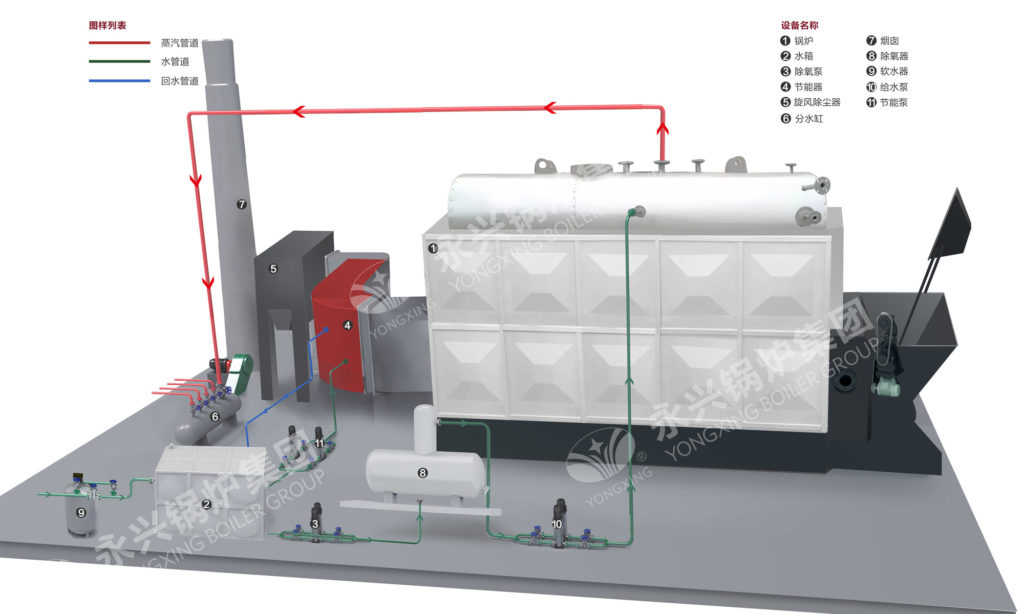

The DZL chain grate boiler is developed by Yongxing Group, it is a single-bowl vertical chain grate boiler which using biomass pellet, wood and other solid fuel. It is a new generation of energy-efficient boiler. Wood and other solid biomass is an ideal renewable energy source, with a large amount of output every year. Using it to replace the combustion of coal can not only reduce costs for enterprises, bring rich economic returns, but also increase waste utilization Farmers’ income has realized the common development of economic and social benefits. This boiler also has the advantages of fast pressure rise, high thermal efficiency, and large heating area.

DZL series wood fired steam boiler is a horizontal three-pass water-fired tube boiler. It is designed with high-efficiency and energy-saving enhanced combustion technology to ensure the full combustion of wood and biomass fuel. It is even better that the volume of the furnace and the embossing chamber is very large, which is conducive to the ashes and sedimentation of fly ash. The dust coarse separation steering chamber set at the exit flue gas window achieves the purpose of dust removal in the boiler furnace, reduces the emission of flue gas, and makes it reach the national environmental protection regulations.

Chain Grate Wood Fired Steam Boiler Features

- The use of a threaded flue pipe for heat transfer improves thermal efficiency and reduces energy consumption.

- The application of the membrane water-cooled wall structure improves the heat transfer coefficient and heat transfer effect, and reduces heat loss.

- The threaded smoke pipe is arranged in the boiler shell, and the overall leakage is small, and the heat loss of the smoke is small.

- The welding seam of the boiler adopts advanced submerged arc automatic welding technology to ensure the welding quality.

- A dust collector is arranged at the tail flue to ensure that the dust emission meets environmental protection requirements.

- High level of automation, with automatic water adjustment, low water level interlock protection, high and low water level alarm and other functions.

- The advanced arch-shaped design forms a clearly inverted "α" flame, which is beneficial to the combustion of inferior wood and has strong adaptability to biomass fuel types.

- Complete control and monitoring instruments, safe and reliable boiler operation.

- The setting of the two-wing flues allows the flue gas to enter the front smoke box smoothly, makes the temperature of the previous tube sheet the same, and avoids tube sheet cracks due to temperature stress.

- The chain grate adopts a new type of small-scale grate, which adds a unique safety ring to make the grate operate stably and reliably and improve the combustion efficiency.

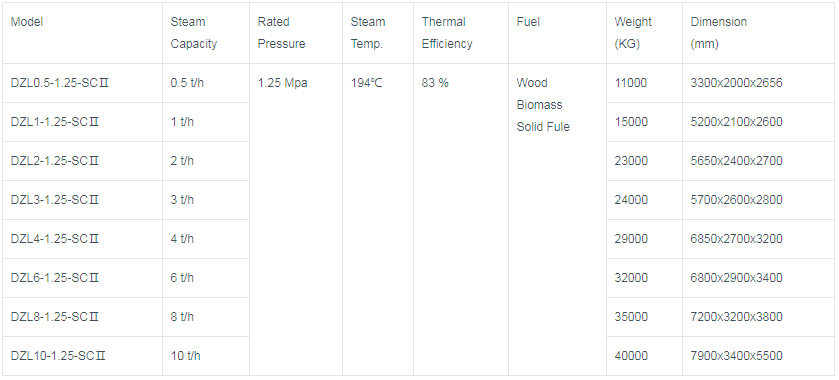

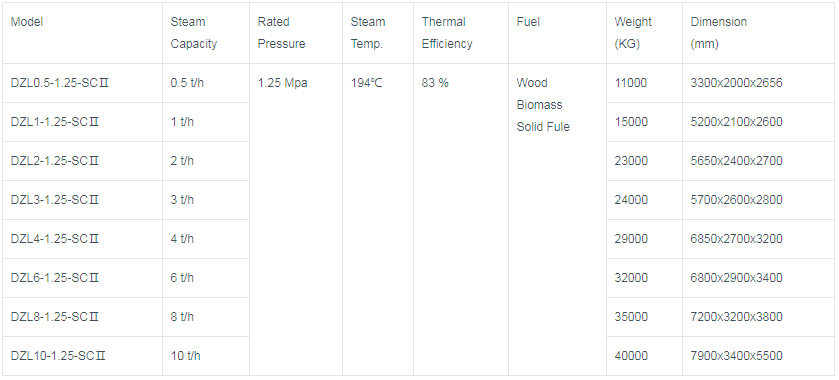

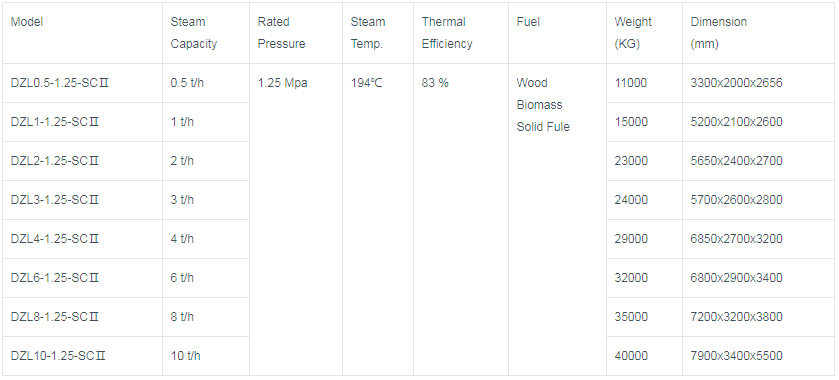

Technical Specification

| Model | Steam Capacity | Rated Pressure | Steam Temp. | Thermal Efficiency | Fuel | Weight (KG) | Dimension (mm) |

| DZL0.5-1.25-SCⅡ | 0.5 t/h | 1.25 Mpa | 194℃ | 83 % | Wood Biomass Solid Fule | 11000 | 3300x2000x2656 |

| DZL1-1.25-SCⅡ | 1 t/h | 15000 | 5200x2100x2600 | ||||

| DZL2-1.25-SCⅡ | 2 t/h | 23000 | 5650x2400x2700 | ||||

| DZL3-1.25-SCⅡ | 3 t/h | 24000 | 5700x2600x2800 | ||||

| DZL4-1.25-SCⅡ | 4 t/h | 29000 | 6850x2700x3200 | ||||

| DZL6-1.25-SCⅡ | 6 t/h | 32000 | 6800x2900x3400 | ||||

| DZL8-1.25-SCⅡ | 8 t/h | 35000 | 7200x3200x3800 | ||||

| DZL10-1.25-SCⅡ | 10 t/h | 40000 | 7900x3400x5500 |