Electric Steam Boiler

Horizontal Electric Steam Boiler

- Capacity: 0.3~4 t/h

- Pressure: 0.7/1/1.25 Mpa

- Steam Temperature: 171/184/194 ℃

- Thermal Efficiency: >98%

- Fuel: Electricity

- Large hotels, schools, bathing, petrochemical, residential areas, chemical, smelting, textile, food factories

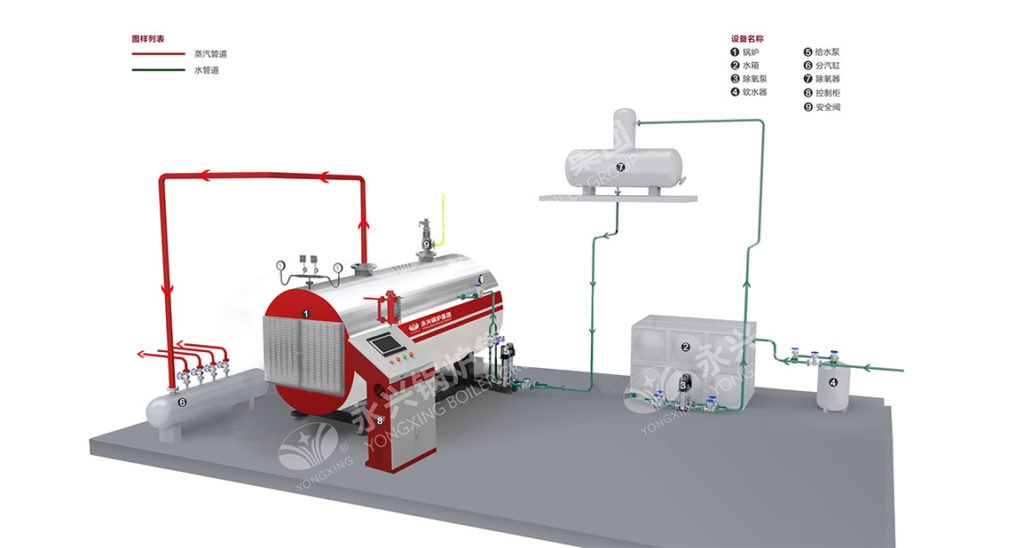

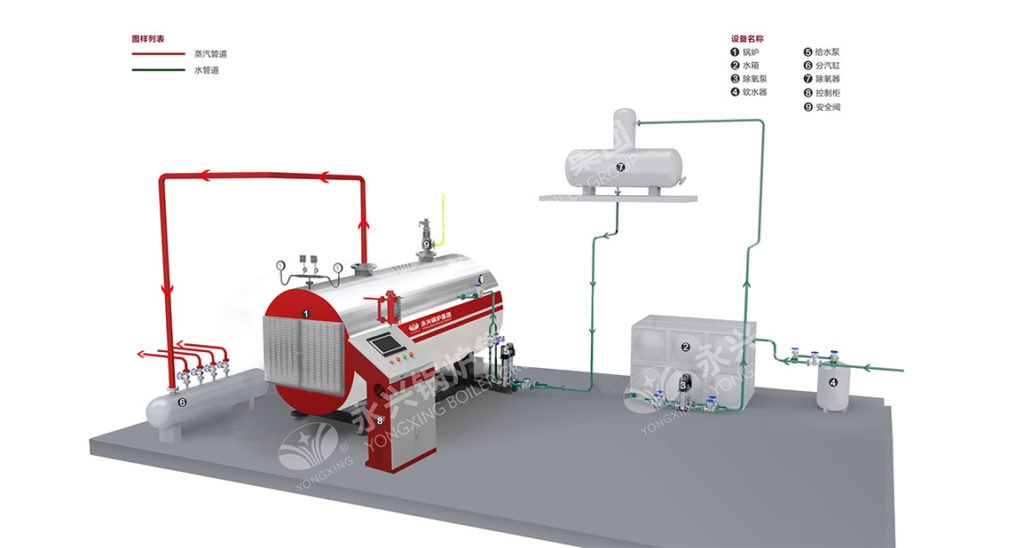

Introduction of Horizontal Electric Steam Boiler

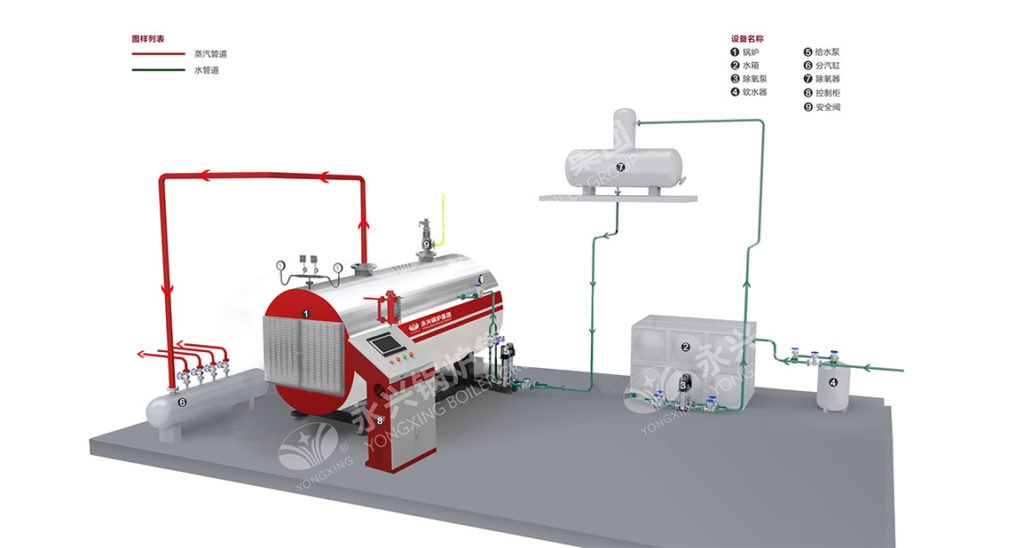

Yongxing WDR type electric steam boiler is a horizontal type boiler using electricity heating. It mainly includes 3 types: electric steam boiler, electric normal pressure hot water boiler and electric high pressure hot water boiler. It uses electricity as heating energy, and does not produce waste gas, waste residue, waste materials during the work process. Our WDR electric steam boiler not only improves the working environment of the workers, but also meets the requirements of national environmental protection policies. Compared with other boilers, it also features low noise, stable operation, convenient operation, and high thermal efficiency.

The WDR electric heating steam boiler adopts the separation method of the electric control cabinet of the boiler body, which avoids the problems caused by thermal aging of the components and improves the service life. The boiler body adopts boiler steel plate, longitudinal and circumferential welds are automatically welded, and X-ray inspection is performed, which not only ensures the quality of the boiler, but also improves the appearance. In addition, it can automatically track and detect the circulation pump, and can control the startup or shutdown of the circulation pump according to the water temperature to meet the requirements of daily work.

Horizontal Electric Steam Boiler Features

- The boiler body is made of high-quality thermal insulation material, which has small heat dissipation loss and reduced energy consumption.

- The perfect combination of the boiler body and the electric control device realizes the mechatronics and reduces the occupied space.

- The electric heating tube and the boiler body are connected by flange, which is convenient for disassembly and maintenance, and it is also very convenient to maintain.

- With automatic memory fault function, easy to view and repair.

- The controller adopts a digital LCD display, full English display, and a graphical operating interface. Users can directly view the device operating parameters through the display.

- The boiler adopts progressive loading or load reduction design, which effectively protects the heating elements, reduces the impact on the power grid, and extends the service life.

- The heating device uses a ceramic electric heating tube whose surface load is several times lower than that of a metal heating tube, which prolongs the service life and improves the thermal efficiency up to 99%.

- The time period of automatic operation of the boiler can be set as required, and it is better to set a plurality of different working hours in a day

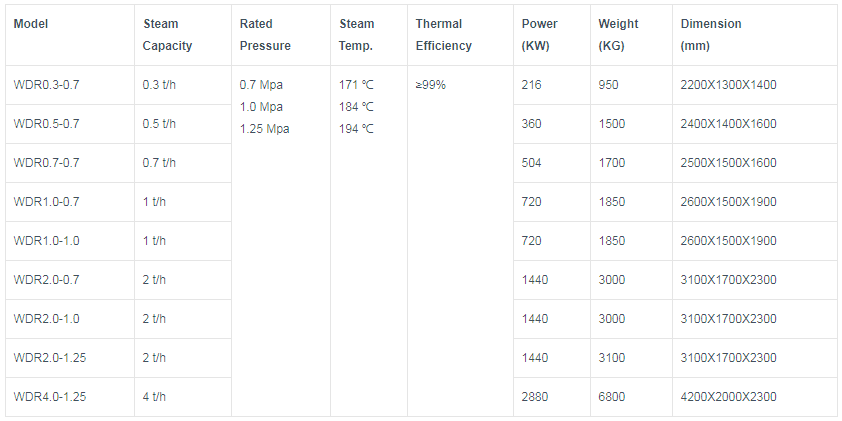

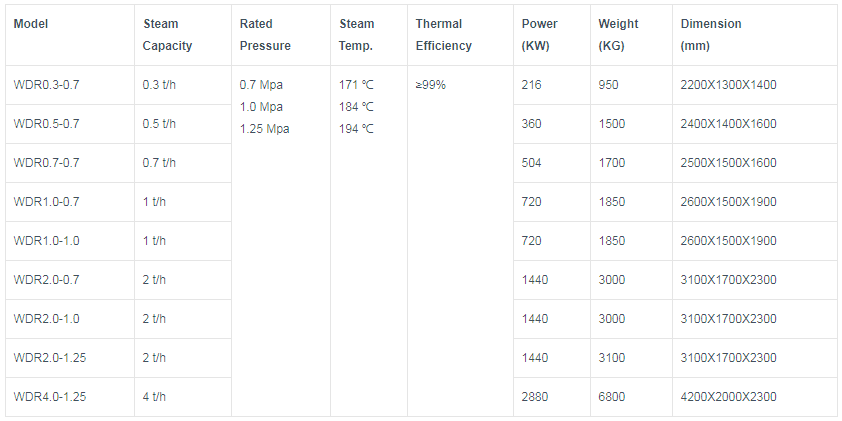

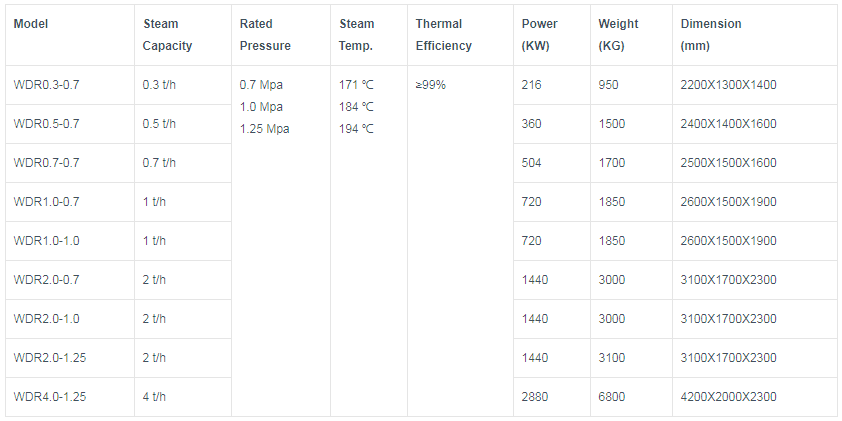

Technical Specification

| Model | Steam Capacity | Rated Pressure | Steam Temp. | Thermal Efficiency | Power (KW) | Weight (KG) | Dimension (mm) |

| WDR0.3-0.7 | 0.3 t/h | 0.7 Mpa 1.0 Mpa 1.25 Mpa | 171 ℃ 184 ℃ 194 ℃ | ≥99% | 216 | 950 | 2200X1300X1400 |

| WDR0.5-0.7 | 0.5 t/h | 360 | 1500 | 2400X1400X1600 | |||

| WDR0.7-0.7 | 0.7 t/h | 504 | 1700 | 2500X1500X1600 | |||

| WDR1.0-0.7 | 1 t/h | 720 | 1850 | 2600X1500X1900 | |||

| WDR1.0-1.0 | 1 t/h | 720 | 1850 | 2600X1500X1900 | |||

| WDR2.0-0.7 | 2 t/h | 1440 | 3000 | 3100X1700X2300 | |||

| WDR2.0-1.0 | 2 t/h | 1440 | 3000 | 3100X1700X2300 | |||

| WDR2.0-1.25 | 2 t/h | 1440 | 3100 | 3100X1700X2300 | |||

| WDR4.0-1.25 | 4 t/h | 2880 | 6800 | 4200X2000X2300 |