Industrial Oil Gas Fired Boiler

Low NOX Emissions Oil and Gas Boiler

- Capacity: 1-20T/0.7-14MW

- Pressure: 1.0, 1.25, 1.6, 2.5 Mpa

- Steam Temperature: 184/194/204/225℃

- Thermal Efficiency: >100.9%

- Fuel: Natural gas, coke oven gas, city gas, heavy oil, palm oil, blast furnace gas

- NOx Emission: 18-30 Mg/M3

Introduction of Low NOX Emissions Oil and Gas Steam Boiler

Yongxing WNS ultra-low NOx emissions fuel oil and gas fired boiler is a shell-type three-pass wet-back oil and gas fired boiler. It is composed of boiler body, steam boiler economizer, condenser, etc. Compared with the old type boiler, its most prominent feature is low nitrogen (the nitrogen oxide emissions during the operation of the boiler are greatly reduced, up to 30mg / m3). In addition, this oil gas boiler has the characteristics of compact structure, beautiful appearance, simple operation, safe and reliable operation, etc., and has been widely used in various industries.

WNS type ultra-low NOx Emission oil and gas fired boiler adopts a full wet back structure, and high temperature flue gas is surrounded by water, which solves the cooling and sealing problems of the smoke return chamber and improves the boiler’s operating environment. The addition of condensers (made with finned tubes) increases the boiler efficiency to more than 98%, saving operating costs. At the same time, the oil and gas fired boiler is equipped with a leakage protection. Once the control system detects a leakage of the electric heating element, the boiler will automatically cut off the power to ensure the safety of workers and the boiler and increase the boiler’s service life.

Oil and Gas Fired Boiler Features

- The protection function is perfect, with water shortage protection and pressure relief protection to ensure the safe and efficient operation of the oil gas boiler.

- The outer shell is made of stainless steel, which greatly increases the corrosion resistance.

- The front and rear smoke box covers of the boiler are movable, which greatly reduces the difficulty of maintenance and improves the efficiency of maintenance.

- The design of the rear view device makes it easy for workers to observe the combustion conditions.

- The condenser is made of special steel that is resistant to sulfuric acid and low dew point corrosion, which improves the service life of the boiler.

- The internal smoke pipe adopts a threaded structure, which improves the heat transfer efficiency and strengthens the heat transfer effect.

- The heating surface is well arranged, so that water circulation and heat circulation are guaranteed, the heat transfer effect is greatly improved, and the optimal state is achieved.

- The control system controls the start and stop of the circulation pump according to the temperature of the boiler water. When the temperature of the boiler water reaches the set upper limit, the hot water circulation pump starts, and when the temperature falls below the set lower limit water temperature, the hot water circulation pump stops.

- A condenser is installed at the end of the boiler, and the waste heat discharged from the tail of the boiler is used to increase the boiler inlet water temperature and reduce the exhaust gas temperature, so that the thermal efficiency of the boiler reaches more than 100%, which saves operating costs.

- The combustion, water level, temperature and steam pressure can all be adjusted and controlled automatically, which not only facilitates the operation of workers, but also improves safety.

Technical Specification

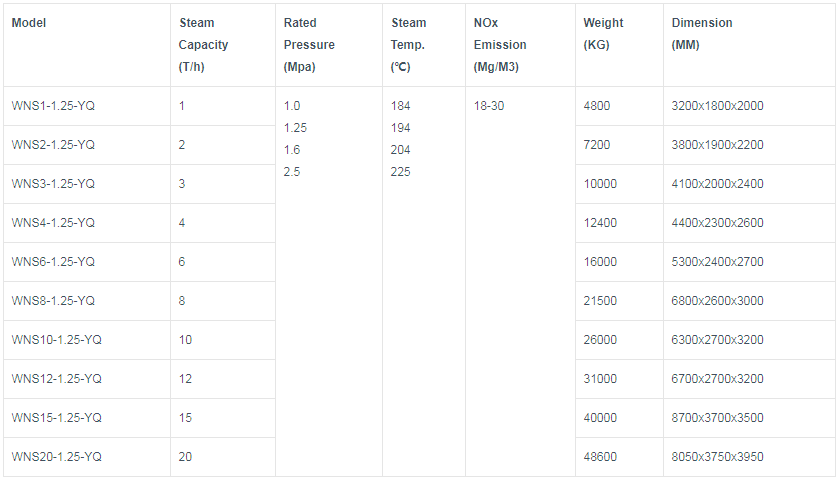

| Model | Steam Capacity (T/h) | Rated Pressure (Mpa) | Steam Temp. (℃) | NOx Emission (Mg/M3) | Weight (KG) | Dimension (MM) |

| WNS1-1.25-YQ | 1 | 1.0 1.25 1.6 2.5 | 184 194 204 225 | 18-30 | 4800 | 3200x1800x2000 |

| WNS2-1.25-YQ | 2 | 7200 | 3800x1900x2200 | |||

| WNS3-1.25-YQ | 3 | 10000 | 4100x2000x2400 | |||

| WNS4-1.25-YQ | 4 | 12400 | 4400x2300x2600 | |||

| WNS6-1.25-YQ | 6 | 16000 | 5300x2400x2700 | |||

| WNS8-1.25-YQ | 8 | 21500 | 6800x2600x3000 | |||

| WNS10-1.25-YQ | 10 | 26000 | 6300x2700x3200 | |||

| WNS12-1.25-YQ | 12 | 31000 | 6700x2700x3200 | |||

| WNS15-1.25-YQ | 15 | 40000 | 8700x3700x3500 | |||

| WNS20-1.25-YQ | 20 | 48600 | 8050x3750x3950 |

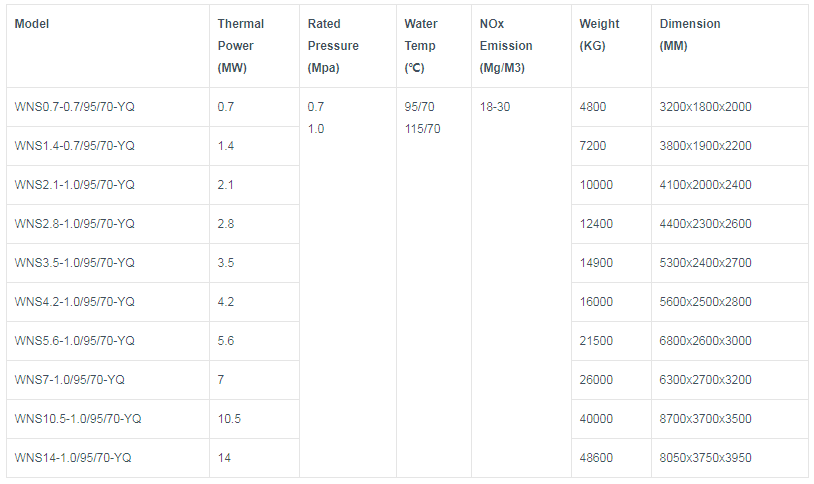

| Model | Thermal Power (MW) | Rated Pressure (Mpa) | Water Temp (℃) | NOx Emission (Mg/M3) | Weight (KG) | Dimension (MM) |

| WNS0.7-0.7/95/70-YQ | 0.7 | 0.7 1.0 | 95/70 115/70 | 18-30 | 4800 | 3200x1800x2000 |

| WNS1.4-0.7/95/70-YQ | 1.4 | 7200 | 3800x1900x2200 | |||

| WNS2.1-1.0/95/70-YQ | 2.1 | 10000 | 4100x2000x2400 | |||

| WNS2.8-1.0/95/70-YQ | 2.8 | 12400 | 4400x2300x2600 | |||

| WNS3.5-1.0/95/70-YQ | 3.5 | 14900 | 5300x2400x2700 | |||

| WNS4.2-1.0/95/70-YQ | 4.2 | 16000 | 5600x2500x2800 | |||

| WNS5.6-1.0/95/70-YQ | 5.6 | 21500 | 6800x2600x3000 | |||

| WNS7-1.0/95/70-YQ | 7 | 26000 | 6300x2700x3200 | |||

| WNS10.5-1.0/95/70-YQ | 10.5 | 40000 | 8700x3700x3500 | |||

| WNS14-1.0/95/70-YQ | 14 | 48600 | 8050x3750x3950 |

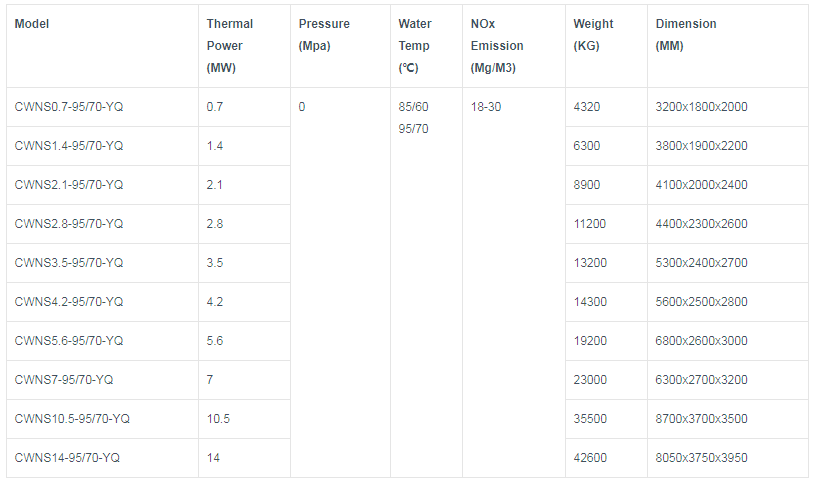

| Model | Thermal Power (MW) | Pressure (Mpa) | Water Temp (℃) | NOx Emission (Mg/M3) | Weight (KG) | Dimension (MM) |

| CWNS0.7-95/70-YQ | 0.7 | 0 | 85/60 95/70 | 18-30 | 4320 | 3200x1800x2000 |

| CWNS1.4-95/70-YQ | 1.4 | 6300 | 3800x1900x2200 | |||

| CWNS2.1-95/70-YQ | 2.1 | 8900 | 4100x2000x2400 | |||

| CWNS2.8-95/70-YQ | 2.8 | 11200 | 4400x2300x2600 | |||

| CWNS3.5-95/70-YQ | 3.5 | 13200 | 5300x2400x2700 | |||

| CWNS4.2-95/70-YQ | 4.2 | 14300 | 5600x2500x2800 | |||

| CWNS5.6-95/70-YQ | 5.6 | 19200 | 6800x2600x3000 | |||

| CWNS7-95/70-YQ | 7 | 23000 | 6300x2700x3200 | |||

| CWNS10.5-95/70-YQ | 10.5 | 35500 | 8700x3700x3500 | |||

| CWNS14-95/70-YQ | 14 | 42600 | 8050x3750x3950 |