Thermal Oil Boiler

YLW Biomass Thermal Oil Heater

- Capacity: 1400KW-7000KW

- Pressure: 1.1 Mpa

- Max Temperature: 320 ℃

- Thermal Efficiency: 83%

- Fuel: Straw, molded lees, bagasse, direct-fired coal, biomass mixed fuel, wood chips, waste wood, biomass pellet

- Large hotels, schools, institutions, clothing and textiles, wineries, central heating, etc.

Introduction of YLW Biomass Thermal Oil Heater

Yongxing YLW biomass heat transfer oil heater is a forced circulation chain grate boiler. It is a new type of heating system using environmental energy wood and biomass as fuel and heat-conducting oil as medium. It consists of an upper heater and a lower chain grate. The front is the heating radiation part, the middle part is a heating surface composed of a serpentine tube bundle, and the rear part is a convection surface. During operation, the boiler can be precisely temperature adjusted according to actual requirements, which can meet different requirements of customers. It is even better that the boiler has a complete operation control system and safety monitoring device, making the operation of the boiler simpler and more convenient. Compared with coal burning, YLW biomass thermal oil heater can save 5% -10% of the cost, so it is the best product to replace coal-fired boiler.

The YLW type biomass oil-conducting oil boiler does not produce corrosion and dirt during operation, and does not generate exhaust gas. In addition, it has the characteristics of good heat transfer performance, convenient and rapid maintenance, and high thermal efficiency. This model meets the requirements of the policy and also meets the new boilers required by customers.

YLW Biomass Thermal Oil Heater Features

- Prior to circulating heating of the boiler, there are technical measures to strictly control the air, moisture and other low volatile matter content in the heating medium.

- The compact structure greatly saves the floor space of the boiler room.

- The boiler body and the chain grate can be combined at the construction site, which not only reduces transportation costs but also shortens the installation time.

- The design of the furnace arch is reasonable, so that the time for the flue gas to stay in the furnace is extended, and the combustion is more sufficient.

- Higher operating temperatures can be obtained at lower operating pressures.

- The thermal efficiency can be maintained at the optimal level under various loads.

- Use wood chips and agricultural and forestry waste as fuel to turn waste into treasure.

- The thermal oil heater is composed of double-dense coils, which reduces the heat load on the surface of the tube and improves safety. There is a heating surface arranged in the smoke chamber, which avoids the short-circuit phenomenon of the smoke caused by the high-temperature smoke directly flushing the partition wall and causing the partition wall to fall.

- The medium flow is reasonable and flows from low to high, making it difficult for the gas generated during operation to remain in the furnace, and it can be conveniently discharged from the system.

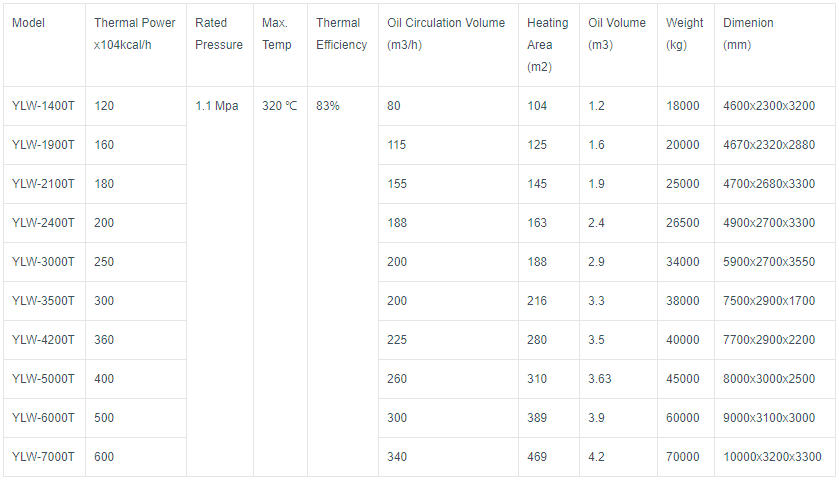

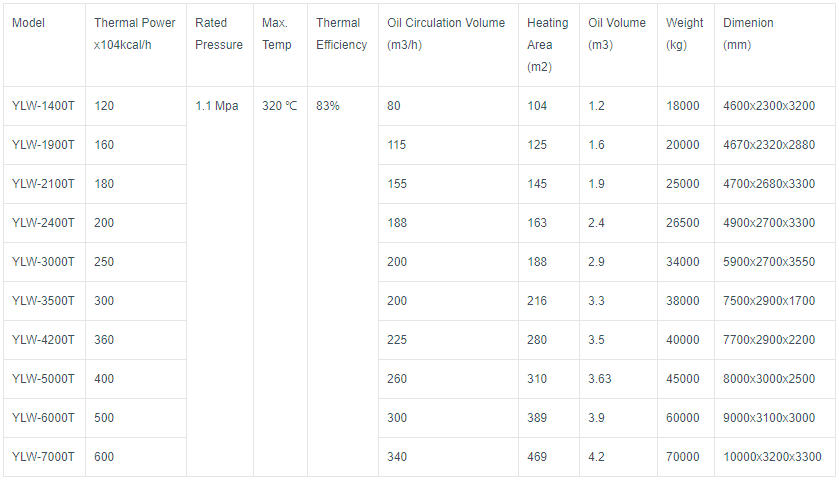

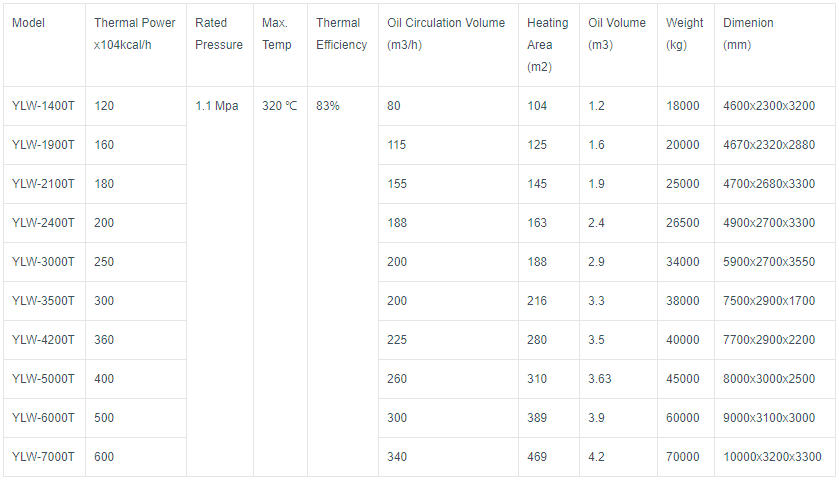

Technical Specification

| Model | Thermal Power x104kcal/h | Rated Pressure | Max. Temp | Thermal Efficiency | Oil Circulation Volume (m3/h) | Heating Area (m2) | Oil Volume (m3) | Weight (kg) | Dimenion (mm) |

| YLW-1400T | 120 | 1.1 Mpa | 320 ℃ | 83% | 80 | 104 | 1.2 | 18000 | 4600x2300x3200 |

| YLW-1900T | 160 | 115 | 125 | 1.6 | 20000 | 4670x2320x2880 | |||

| YLW-2100T | 180 | 155 | 145 | 1.9 | 25000 | 4700x2680x3300 | |||

| YLW-2400T | 200 | 188 | 163 | 2.4 | 26500 | 4900x2700x3300 | |||

| YLW-3000T | 250 | 200 | 188 | 2.9 | 34000 | 5900x2700x3550 | |||

| YLW-3500T | 300 | 200 | 216 | 3.3 | 38000 | 7500x2900x1700 | |||

| YLW-4200T | 360 | 225 | 280 | 3.5 | 40000 | 7700x2900x2200 | |||

| YLW-5000T | 400 | 260 | 310 | 3.63 | 45000 | 8000x3000x2500 | |||

| YLW-6000T | 500 | 300 | 389 | 3.9 | 60000 | 9000x3100x3000 | |||

| YLW-7000T | 600 | 340 | 469 | 4.2 | 70000 | 10000x3200x3300 |