Industrial Superheated Steam Boiler

SZS Industrial Superheated Steam Boiler

- Capacity: 6-150T/4.2-105MW

- Pressure: 1.25, 1.6, 2.5 Mpa

- Steam Temperature: 194/204/225℃

- Superheated Steam Temperature: 350/400℃

- Thermal Efficiency: 93.3~97%

- Fuel: Natural gas, city gas, light oil, heavy oil, biogas, blast furnace gas

Introduction of SZS Oil and Gas Industrial Superheated Steam Boiler

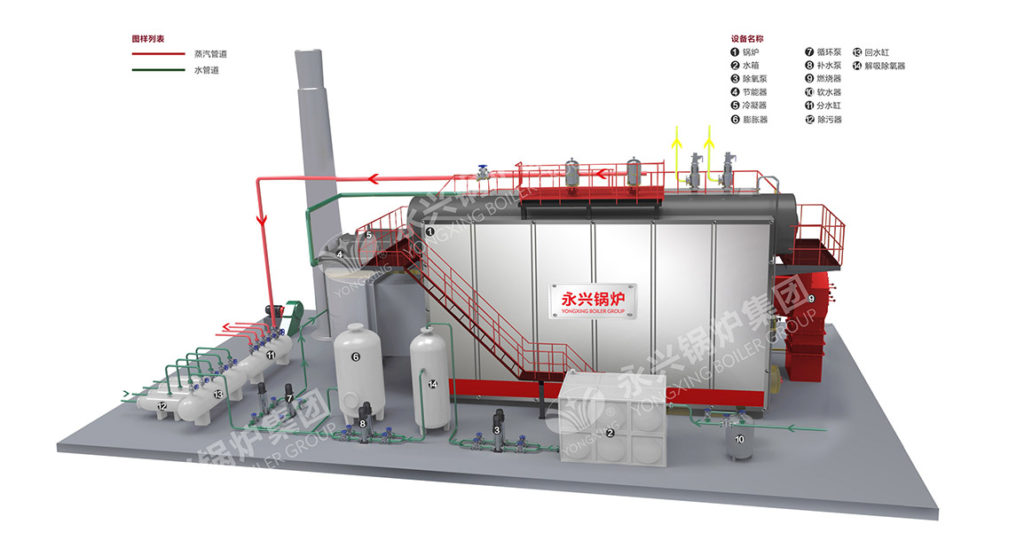

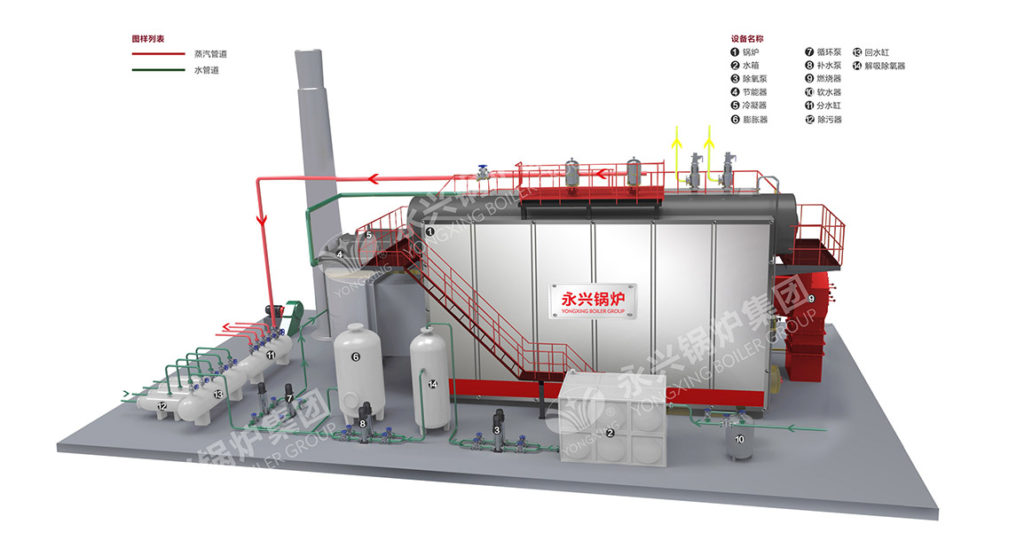

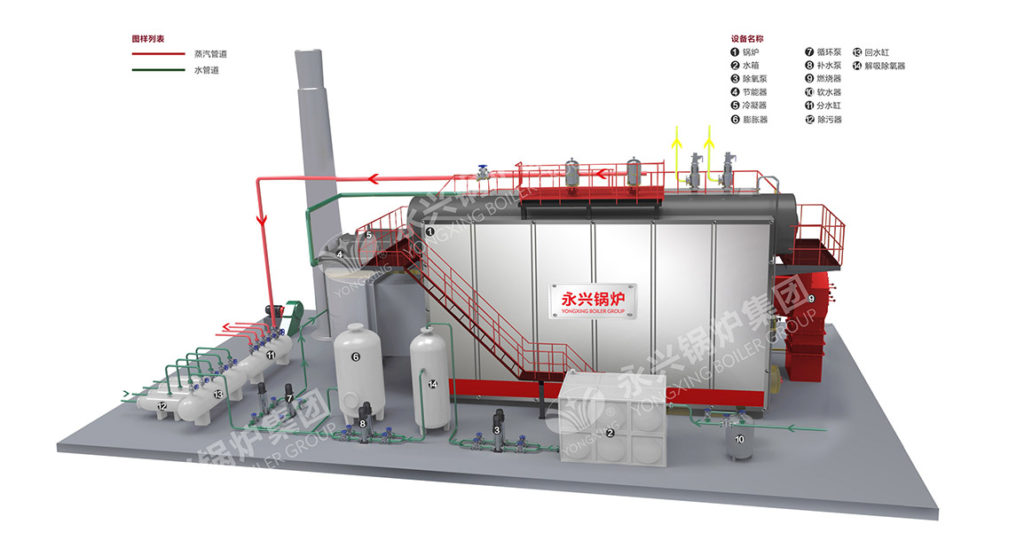

SZS oil gas fired boiler is a double drum vertical combustion industrial boiler. It consists of upper and lower boiler drums, membrane water-cooled walls, burners, superheaters, convection tube bundles, economizers, and decontaminants. Boiler water-cooled wall and convection flue adopt membrane wall structure, which reduces the use of refractory bricks. In addition, the boiler has the advantages of energy saving, high efficiency, environmental protection, short installation period, fully automatic operation, simple operation, and perfect protection functions. It can meet the needs of industrial heating and the heating needs of small power stations. It is one of Yongxing best sales industrial boiler on the market.

This Industrial boiler is a quick assembly and bulk water tube boiler, with the convection tube bundle on the left and the hearth on the right. During the heating process, the flue gas produced by the combustion of the furnace enters the ashes chamber and the convection tube bundle area from the smoke outlet at the tail of the furnace, and then turns to the energy saver and condenser made of finned tubes, and finally passes through the flue and chimney and discharged into the air. The application of energy savers and air conditioners not only reduces the exhaust temperature, improves the thermal efficiency, and also reduces the fuel consumption.

SZS Superheated Steam Boiler Features

- D-type structure design, compact structure, small volume, good flame fullness.

- Both the front and rear walls adopt a membrane water-cooled wall structure to ensure a service life of more than 20 years.

- The arrangement of the manholes at the front and back of the upper and lower drums and the arrangement of the inspection door at the rear of the boiler facilitate the user's maintenance and cleaning of the interior and exterior.

- Micro-positive pressure combustion improves the thermal efficiency of the boiler and reduces operating costs.

- Reliable water circulation system to ensure that no vaporized water hammer occurs in the pipe.

- The arrangement of explosion-proof doors and flame detectors makes the boiler safe and reliable.

- The thermal insulation layer of the boiler adopts high thermal resistance material, which has good thermal insulation performance.

- Concave and convex guards on the exterior not only ensure the excellent sealing performance of the boiler, but also beautify the appearance quality.

- The three-return convection tube bundle design extends the time for the flue gas to stay in the furnace, makes the fuel burn more fully, and improves the combustion efficiency.

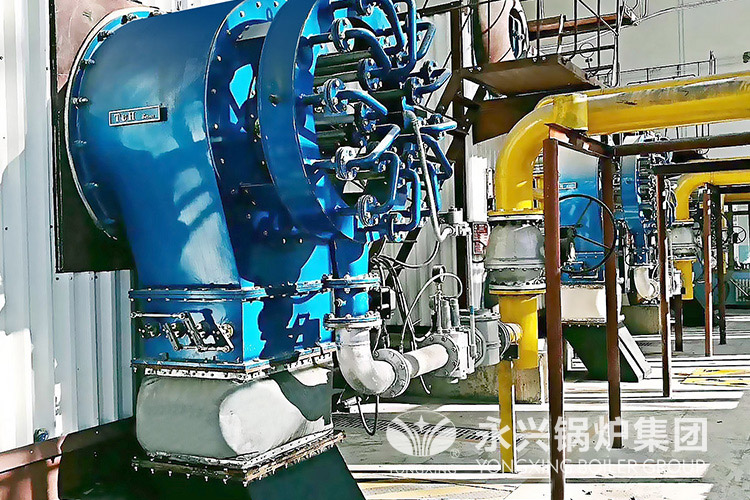

- The boiler uses a fully automatic burner, which has higher combustion efficiency than traditional boilers. Protection functions such as over pressure and flameout improve the safety of workers.

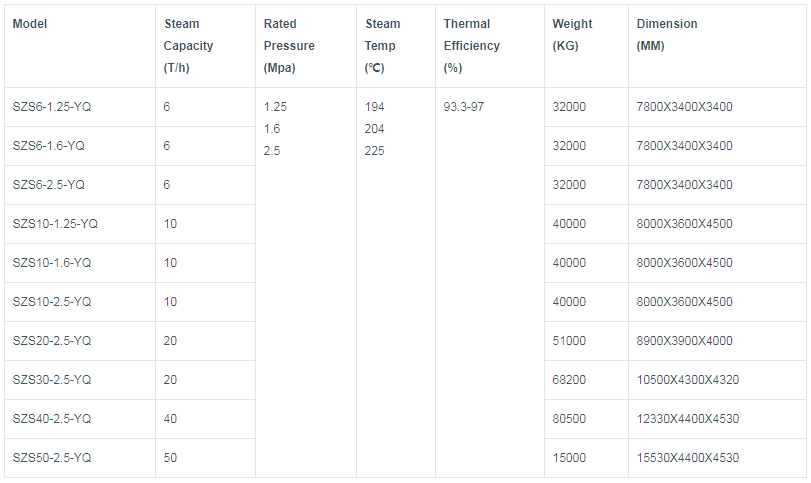

Technical Specification

| Model | Steam Capacity (T/h) | Rated Pressure (Mpa) | Steam Temp (℃) | Thermal Efficiency (%) | Weight (KG) | Dimension (MM) |

| SZS6-1.25-YQ | 6 | 1.25 1.6 2.5 | 194 204 225 | 93.3-97 | 32000 | 7800X3400X3400 |

| SZS6-1.6-YQ | 6 | 32000 | 7800X3400X3400 | |||

| SZS6-2.5-YQ | 6 | 32000 | 7800X3400X3400 | |||

| SZS10-1.25-YQ | 10 | 40000 | 8000X3600X4500 | |||

| SZS10-1.6-YQ | 10 | 40000 | 8000X3600X4500 | |||

| SZS10-2.5-YQ | 10 | 40000 | 8000X3600X4500 | |||

| SZS20-2.5-YQ | 20 | 51000 | 8900X3900X4000 | |||

| SZS30-2.5-YQ | 20 | 68200 | 10500X4300X4320 | |||

| SZS40-2.5-YQ | 40 | 80500 | 12330X4400X4530 | |||

| SZS50-2.5-YQ | 50 | 15000 | 15530X4400X4530 |

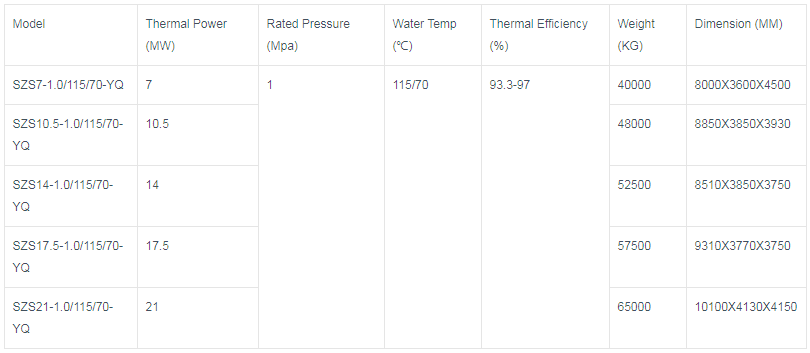

| Model | Thermal Power (MW) | Rated Pressure (Mpa) | Water Temp (℃) | Thermal Efficiency (%) | Weight (KG) | Dimension (MM) |

| SZS7-1.0/115/70-YQ | 7 | 1 | 115/70 | 93.3-97 | 40000 | 8000X3600X4500 |

| SZS10.5-1.0/115/70-YQ | 10.5 | 48000 | 8850X3850X3930 | |||

| SZS14-1.0/115/70-YQ | 14 | 52500 | 8510X3850X3750 | |||

| SZS17.5-1.0/115/70-YQ | 17.5 | 57500 | 9310X3770X3750 | |||

| SZS21-1.0/115/70-YQ | 21 | 65000 | 10100X4130X4150 |

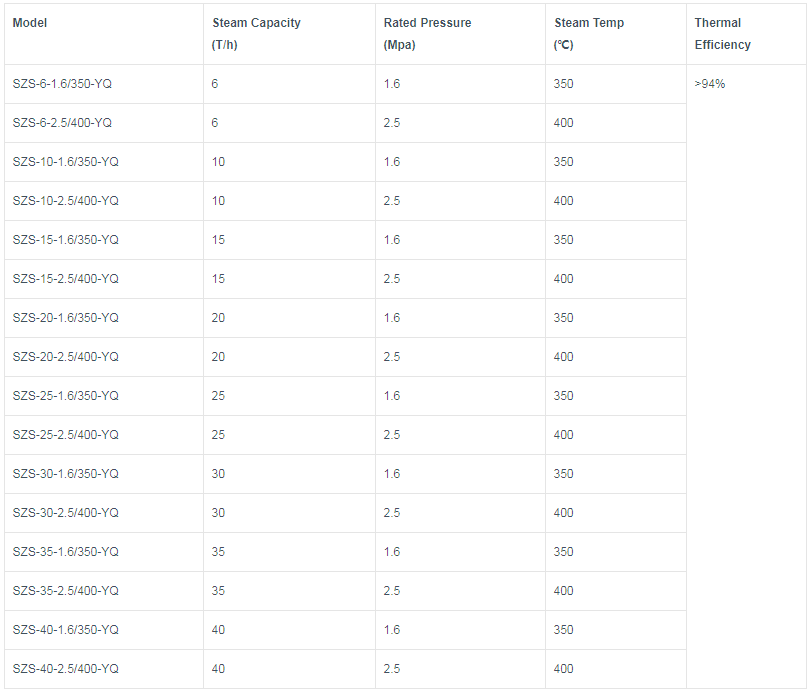

| Model | Steam Capacity (T/h) | Rated Pressure (Mpa) | Steam Temp (℃) | Thermal Efficiency |

| SZS-6-1.6/350-YQ | 6 | 1.6 | 350 | >94% |

| SZS-6-2.5/400-YQ | 6 | 2.5 | 400 | |

| SZS-10-1.6/350-YQ | 10 | 1.6 | 350 | |

| SZS-10-2.5/400-YQ | 10 | 2.5 | 400 | |

| SZS-15-1.6/350-YQ | 15 | 1.6 | 350 | |

| SZS-15-2.5/400-YQ | 15 | 2.5 | 400 | |

| SZS-20-1.6/350-YQ | 20 | 1.6 | 350 | |

| SZS-20-2.5/400-YQ | 20 | 2.5 | 400 | |

| SZS-25-1.6/350-YQ | 25 | 1.6 | 350 | |

| SZS-25-2.5/400-YQ | 25 | 2.5 | 400 | |

| SZS-30-1.6/350-YQ | 30 | 1.6 | 350 | |

| SZS-30-2.5/400-YQ | 30 | 2.5 | 400 | |

| SZS-35-1.6/350-YQ | 35 | 1.6 | 350 | |

| SZS-35-2.5/400-YQ | 35 | 2.5 | 400 | |

| SZS-40-1.6/350-YQ | 40 | 1.6 | 350 | |

| SZS-40-2.5/400-YQ | 40 | 2.5 | 400 |

Superheated Steam Application

1) Superheated steam food processing, to improve the taste of food without additives. Processing in hypoxic or microaerobic environment can inhibit the decay and oxidation of food. Superheated steam can finish surface sterilization in a short time. Pesticides such as antifungal agents sprayed on the surface of fresh fruits can mostly vaporize.

Improve sterilization of food by sterilizing, inhibiting oxidation, generating condensation film by high-speed overheating, and inactivating enzymes. By alpha-starching starch, saccharification and protein denaturation are promoted. Cooking with superheated steam at a temperature of up to 340 ° C, to achieve a healthy cooking effect of deoiling and reducing salt.

2. Superheated drying of food, feed, medicine, biomass. The low-pressure superheated steam drying method combines the advantages of superheated steam, negative pressure and even vacuum drying to expand the adaptability of superheated steam drying to heat-sensitive materials. For foods such as potato chips, noodles, soybeans, rice, vegetables, shrimp, chicken, various fruit slices, etc., Different from tranditional hot air drying, superheated steam-dried foods are not only energy-saving and environmentally friendly, but also highlighted in a short drying time , Material shrinkage and deformation is small, the color remains fresh, porous, good rehydration and high vitamin content.

3. Sludge drying. Superheated steam type sludge drying equipment has the advantages of high drying efficiency, small equipment selection, and low equipment investment. At the same time, it can achieve energy saving, no exhaust emissions, no pollution, and no sludge waste .

4. Treatment of contaminated soil, decomposing and removing PCB, VOC, dioxin and other substances in contaminated soil.

5. Disposal of printed circuit boards (pre-treatment equipment for metal recycling).

6. Fly ash desalination.

7. Preliminary treatment of industrial waste disposal machines.

8. The application of superheated steam in the reuse market is mainly manifested in the degreasing treatment of mechanical oil, the recycling of waste plastics, painting and drying, washing and sterilization.

9. Sauna and bath industry