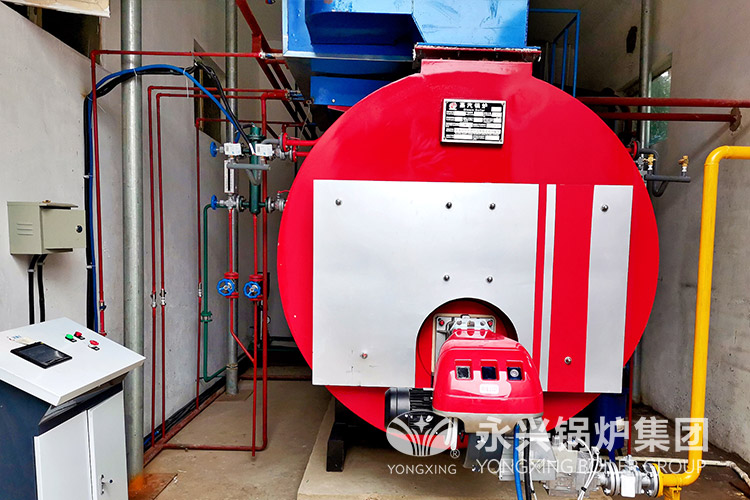

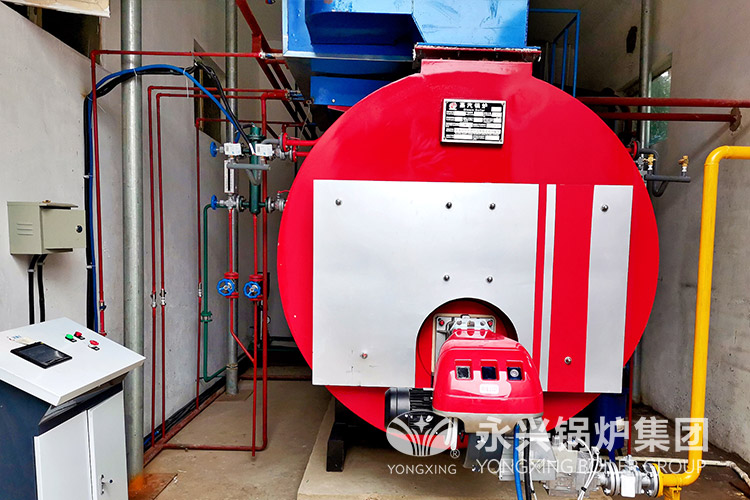

Industrial Gas Steam Boiler

WNS Natural Gas Steam Boiler

- Capacity: 0.5-20T/0.35-14MW

- Pressure: 0.7, 1.0, 1.25, 1.6, 2.5 Mpa

- Steam Temperature: 171, 184, 194, 204, 225 ℃

- Thermal Efficiency: >100.9%

- Fuel: Natural gas, coke oven gas, city gas, light oil, heavy oil

- Hotels, food, building materials, paper mills, feed mills, institutions, residential heating, heating, etc.

Introduction of Gas Steam Boiler

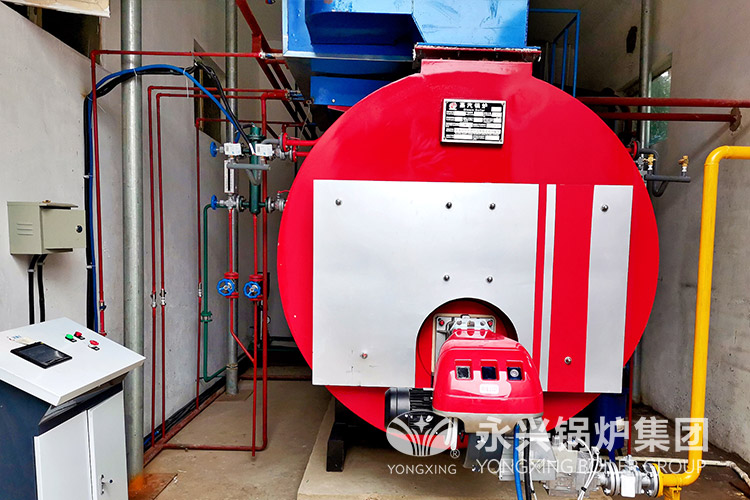

WNS series horizontal internal combustion fuel oil (gas) quick-install boiler adopts wet-back structure. The corrugated furnace and the flashback chamber are the first return stroke, and the second return stroke consists of a smoke pipe, and the condenser is arranged in two stages on the upper part of the boiler. The boiler is equipped with a complete automatic control device and safety protection device, with high and low water level alarms and low water level interlocking protection functions, overpressure alarm and overpressure interlock protection functions; automatic boiler ignition, automatic adjustment of burner fire power and flameout protection to ensure the safe operation of the boiler.

The fuel of this product is light oil or natural gas; the fuel is ejected from the burner, ignited by the electronic ignition rod, and burns with a slight positive pressure in the furnace liner. From the upper part of the front smoke box, turn 180 ° to enter the secondary condenser, and the primary condenser will be discharged into the atmosphere by entering the chimney after heat exchange.

Gas Fired Steam Boiler Features

- Horizontal full wet back structure, one-piece design, small footprint.

- The design of the large hearth and the threaded flue pipe increases the heat absorption of the hearth and reduces energy consumption.

- Various built-in protection devices, such as over temperature, over pressure, water shortage, etc., ensure the safe and reliable operation of the gas steam boiler. The use of threaded flue pipes and corrugated furnace bladder enhances the heat transfer effect and saves fuel.

- The LCD screen displays the working conditions, which is convenient for grasping the operating status of the steam boiler and the system. Equipped with explosion-proof door, it will rebound automatically after pressure release to ensure the safety.

- The condensing waste heat recovery device can repeatedly absorb the smoke and gas discharged from the gas steam boiler, which improves the energy efficiency. The design of the heating surface structure is reasonable, which reduces and controls the smoke resistance.

- Complete protection functions ensure safe and efficient operation of WNS gas steam boiler.

- Multiple boilers can be connected to the network, and the number of operating units can be automatically selected to distribute the load of each boiler.

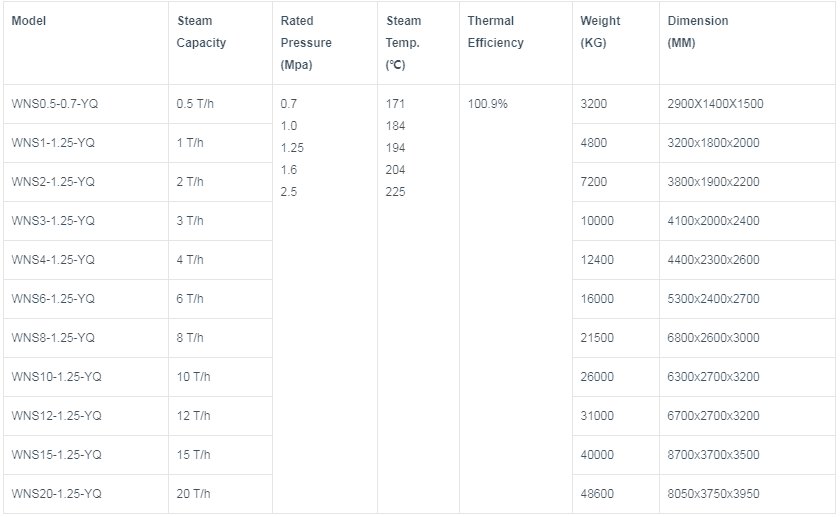

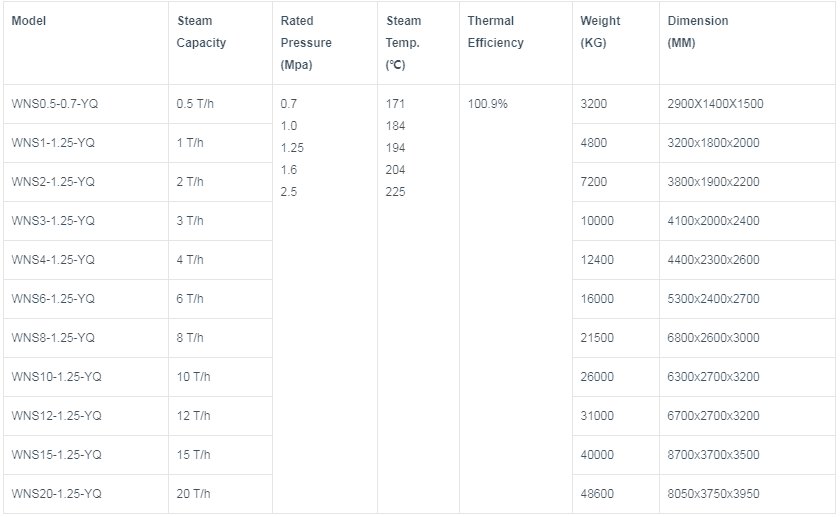

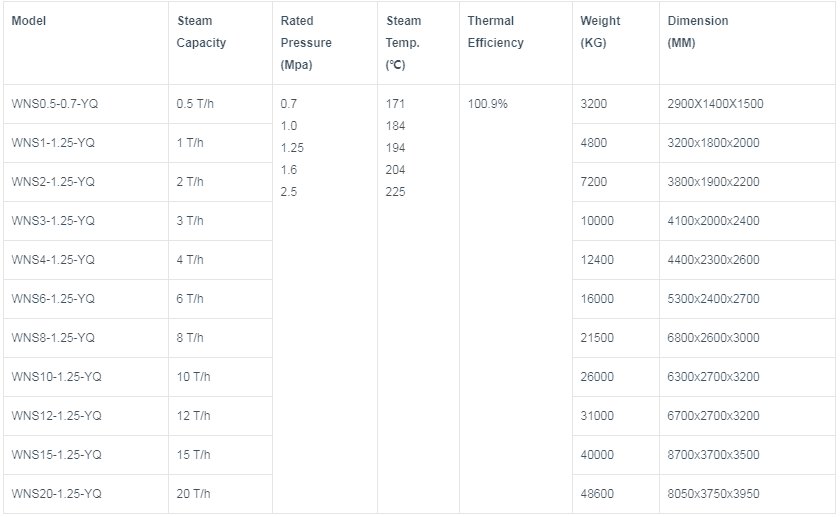

WNS Gas Steam Boiler Technical Specification

| Model | Steam Capacity | Rated Pressure (Mpa) | Steam Temp. (℃) | Thermal Efficiency | Weight (KG) | Dimension (MM) |

| WNS0.5-0.7-YQ | 0.5 T/h | 0.7 1.0 1.25 1.6 2.5 | 171 184 194 204 225 | 100.9% | 3200 | 2900X1400X1500 |

| WNS1-1.25-YQ | 1 T/h | 4800 | 3200x1800x2000 | |||

| WNS2-1.25-YQ | 2 T/h | 7200 | 3800x1900x2200 | |||

| WNS3-1.25-YQ | 3 T/h | 10000 | 4100x2000x2400 | |||

| WNS4-1.25-YQ | 4 T/h | 12400 | 4400x2300x2600 | |||

| WNS6-1.25-YQ | 6 T/h | 16000 | 5300x2400x2700 | |||

| WNS8-1.25-YQ | 8 T/h | 21500 | 6800x2600x3000 | |||

| WNS10-1.25-YQ | 10 T/h | 26000 | 6300x2700x3200 | |||

| WNS12-1.25-YQ | 12 T/h | 31000 | 6700x2700x3200 | |||

| WNS15-1.25-YQ | 15 T/h | 40000 | 8700x3700x3500 | |||

| WNS20-1.25-YQ | 20 T/h | 48600 | 8050x3750x3950 |